Into the Deep

Proceed with Confidence!

Founded in 1993, Armosan is a family company established to meet the demand for steel supports, bolts, and bolt plates used in tunnel construction in our country and to serve Turkey’s distinguished main contractors.

Armosan manufactures steel (lattice, profile) supports for metro tunnels, highway tunnels, and mining tunnels in Turkey, and continues to expand its production diversity.

Our company has successfully been a part of major projects in Turkey, from the Taksim – Levent metro line project, whose construction began in 1993, to the Marmaray tube crossing project. Currently, we provide supply and consultancy support to numerous projects both domestically and internationally.

With over 30 years of experience and a structure that continuously renews itself in terms of technology, Armosan remains one of the successful and reliable companies in the industry.

Moya Grup, taking into account the strong demand from our valued business partners and the value that domestic production would bring to our country, laid the foundations of Armosan Hot Rolled Seamless Pipe Industry and Trade Inc. in 2011 and put it into service in 2013. The company began production of self-drilling rock bolts (IBO bolts) on a 15,000 m² open and 4,000 m² closed area.

The alloy steel we use as raw material is certified and subjected to all necessary tests in accordance with international standards specifically for IBO bolt production before being put into the manufacturing process.

Experience

Production Area

Why Armosan?

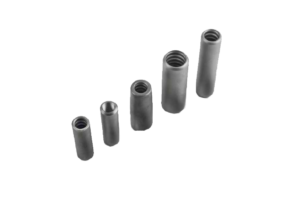

- IBO bolts are produced by threading round-sectioned screws onto the outer surface of pipes manufactured according to API standards using the hot rolling method.

- The round-sectioned screw form facilitates the assembly of the drill bit, sleeve, and nut. It also enhances the bonding performance of concrete to the bolt.

- The ability to perform drilling and injection processes in a single step without changing equipment reduces anchoring time per hole by half.

- It enables drilling with low-cost, disposable drill bits, eliminating the need for expensive drill tips.

- It is the most ideal system for ensuring that the injection process fills the hole perfectly, starting from the tip to the mouth of the hole.

- Thanks to its easy extension feature, it allows for deeper and faster anchoring compared to other anchoring systems. Using a sleeve, it enables drilling and injection up to 30 meters deep.

- Unlike other anchoring systems, there is no need for pre-drilling or using anchor pipes. It also ensures hole stabilization during drilling.

- It provides the ability to create strong anchors with minimal volume, optimizing the need for human and machine power.

- It can be produced in various cross-sections and diameters, allowing for the creation of a system suitable for the tensile strength required by the project.

Business Area

Tunneling, Mining, Hydroelectric Plant and Civil Construction

Business Mix

100% production of Self-drilling anchor bolt’s with hot-drawing method

Capacity

Our factory has, 4.000 m² covered space and 5.000 m² additional capacity is ready for on going projects

Our Quality Certificates